Outdated compliance practices aren't viable amid evolving market and regulatory changes. IQVIA’s award-winning, end-to-end quality management system streamlines the product value chain, accelerates market entry, safeguards companies and patient safety, and meets complex regulatory demands.

- Blogs

- How to Optimize Effective Design Control in Medical Device Manufacturing

Design control is not a new concept, or even a new requirement, but a longstanding tradition in medical device manufacturing. Since 1990, the FDA has demanded medical device manufacturers comply with the criteria outlined in 21 CFR 820.30. These requirements aim to ensure medical devices marketed in the U.S. meet applicable standards and address the needs of patients and other users.

Reviewing The Regulatory Landscape

The FDA is not the only regulatory authority requesting compliance. The EU MDR’s Second Annex (plus that of the IVDR) also require medical device manufacturers to establish and maintain design control procedures. Companies must provide evidence the procedures are followed in the form of complete, up-to-date design and manufacturing information. The documentation must be thorough and enable a clear understanding of the various design stages applied to each device. The international standard ISO 13485 also covers design and development at section 7.3.

SmartSolve’s Design Control Module

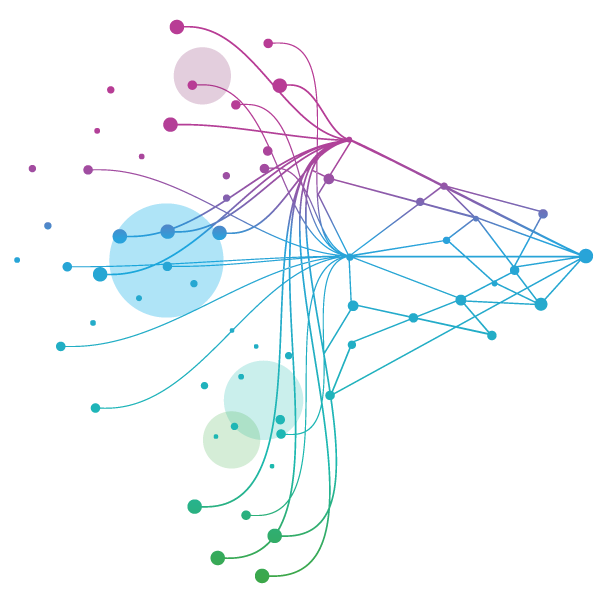

Enter SmartSolve's design control solution, which enables manufacturers to manage the process for all design phases. From design planning to recording inputs and outputs, through verification and validation, to transferring the design to manufacturing, the solution delivers task management functions that accommodate and promote cross-departmental collaboration. This enables subject experts to record all design evidence and comments.

Consistent Results with Policy-Driven Processes

As with other SmartSolve modules, the design control process is policy-driven and based on setup, enabling it to deliver consistent system results. The module offers a gated workflow process, by default, ensuring each design phase is approved before the next begins. However, the workflow provides a project owner flexibility to override and initiate parallel phases as needed. Automated and ad-hoc Design Reviews are an integral step in the workflow. These are initiated as each phase’s requirements are complete.

Superior Design Control Functionality

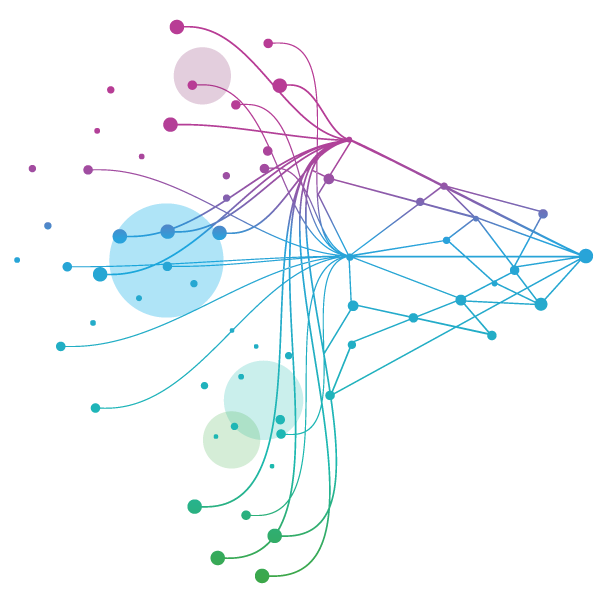

SmartSolve’s Design Control module enables manufacturers to optimize operations with multiple useful functions. These include providing quick access to the design history as well as dashboards and global search functions, which further simplify access to information. In addition, integration with document and repository management allows companies to maintain all their design data and documentation in one readily accessible location. The design control module integrates with medical device manufacturers’ key quality systems, including:

- Document management for design history, as well as authoring and collaboration

- Change management, which allows users to easily create and cross-reference change plans for more structured or complex document changes

- The ability to reference external systems and data

The Benefits of Effective Design Control

The benefits of effective design control impact manufacturers as well as patients. Robust design control improves product safety, performance, and overall product quality. Process efficiency shortens cycle times by providing quick access to key tasks and approvals. A guided-yet-flexible workflow improves the end-to-end process and provides control and consistent execution of tasks without duplicating effort.

Effective design control also enables manufacturers to avoid potential compliance issues because all records, from pre-market design to post-market data collection and design change, are cross-referenced in one integrated system. Manufacturers can demonstrate that a controlled and documented process is in place and has been executed properly.

Finally, effective design control ensures all design, quality, and regulatory data is inspection ready. This factor eases the burden on manufacturers when preparing for audits and helps reduce errors and audit findings.

Gain Management & Visibility into Quality Processes

Medical device manufacturers must comply with design control regulations to ensure that specific device requirements are met. However, with SmartSolve’s new module doing all the heavy lifting, the advantages are numerous for both manufacturers and patients.

Interested in exploring SmartSolve eQMS for your business? Reach out to us at Regulatory_Quality_Compliance@iqvia.com or visit our website here: IQVIA.com/SmartSolve.

Related solutions

From manufacturing oversight to regulatory requirements, manage quality across your organization with a single enterprise software solution.