Take the work and risk out of compliance.

- Library

- Quality Maturity for Life Sciences

With pressures to drive down costs, remain compliant, and improve innovation and the safety of products, manufacturers across all industries are increasing their focus on quality management.

Executives are relying on a variety of resources — across people, processes, and technology — to progress forward and achieve process excellence. But before a company begins an initiative related to improving quality maturity, it’s important to understand the various phases of maturity and to define objectives for how to advance maturity from one phase to the next.

WHAT IS IQVIA’S QUALITY MATURITY MODEL FOR LIFE SCIENCES?

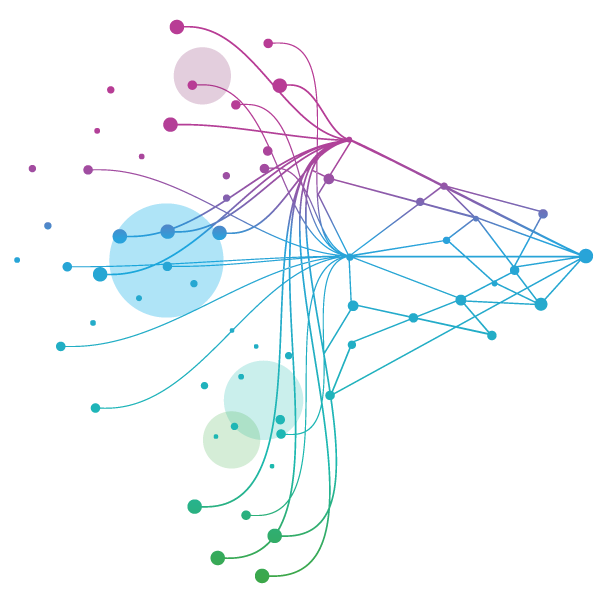

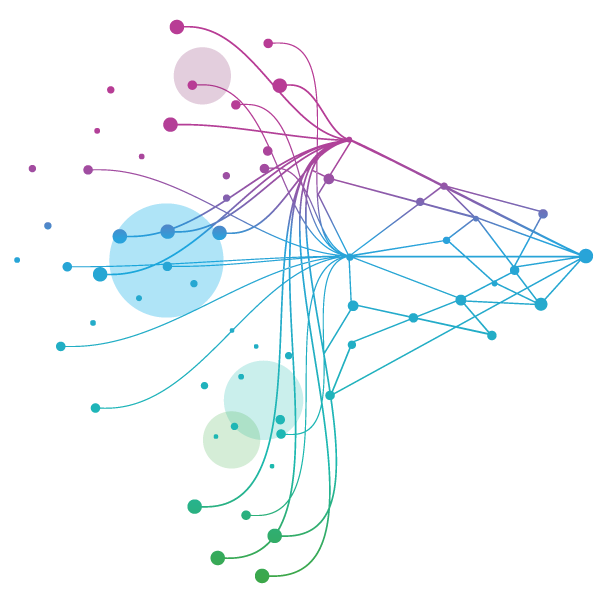

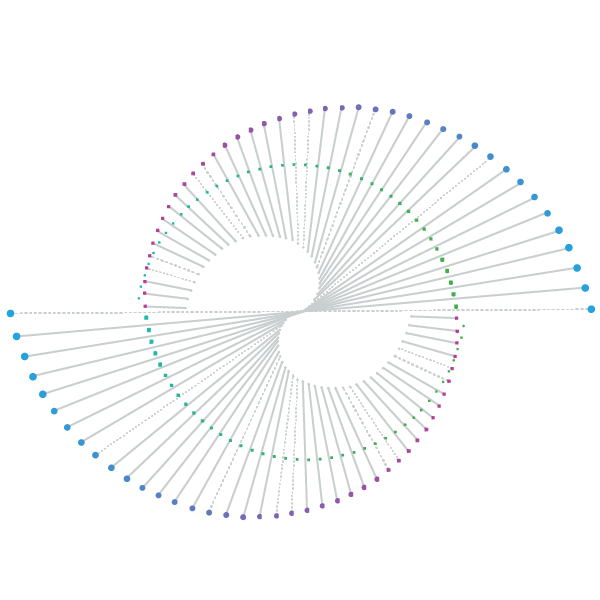

We approach quality challenges from a maturity perspective. At any given time, a company’s maturity level falls within a range that scales from development (low-quality maturity) to leadership (high maturity). In our framework, quality maturity is driven by people and processes, and fueled by technology. Our goal is to help our customers get to higher stages of maturity to gain the benefits of higher product quality, improved compliance, and reductions in overall cost of quality.

In the beginning stages of maturity, processes are manual and reactive. They’re mainly compliance-driven as opposed to driven by quality improvement. Many organizations in this stage are facing the challenges of GMP readiness and compliance with new and evolving regulations, such as EU MDR for the medical device industry. At this phase of maturity, quality is seen more as a function or department. Many businesses at this phase are using a variety of point technology solutions that aren’t integrated with one another, or they are still using paper-based processes. These contribute to an overall lack of visibility and accountability for quality processes and results.

As organizations increase in maturity, the focus moves to prevention and the organization becomes better able to anticipate and manage risk. This can be driven and supported by integrated quality and IT systems.

In higher stages of quality maturity, companies become more proactive and can harmonize processes across the business and even beyond their four walls to better manage supplier quality and activities. At the highest level of maturity, organizations begin developing a true culture of quality with end-to-end quality processes and the ability for metrics to help sustain and improve overall quality.

It’s also possible to move back and forth between quality maturity levels. It takes ongoing management commitment and a continuous improvement effort to drive maturity forward and to sustain it.

HOW DO INCREASING LEVELS OF QUALITY MATURITY BENEFIT THE BUSINESS?

As organizations advance on the quality journey, they can more effectively address regulatory challenges, better manage risk, and bring quality systems into alignment.

One of the key impacts that we see is the impact to overall cost of quality. In our customer interactions, we’ve seen a significant decrease in overall Cost of Quality by advancing even one level in quality maturity. For example, moving from Level 2 (Controlled) to Level 3 (Integrated) can reduce overall Cost of Quality by 6-7%. The figure below provides additional details on cost of quality metrics for various levels of quality maturity.

DOWNLOAD TO LEARN MORE

Related solutions

Related solutions

Outdated compliance practices aren't viable amid evolving market and regulatory changes. IQVIA’s award-winning, end-to-end quality management system streamlines the product value chain, accelerates market entry, safeguards companies and patient safety, and meets complex regulatory demands.

Discover how AI and ML reduce risk and increase efficiency in adverse event reporting

From manufacturing oversight to regulatory requirements, manage quality across your organization with a single enterprise software solution.

Automate and standardize your regulatory management, from correspondence and commitments to registration and tracking.

IQVIA Vigilance Platform is our secure SaaS environment built to simplify safety and PV processes, while boosting speed, accuracy, and efficiency.

Harness the power of automation to execute streamlined end-to-end safety solutions while reducing costs.

Meet the challenge of changing stakeholder demands and increasing cost constraints with IQVIA's integrated technology services and analytics-driven offerings.