Combine data science, technology, and analytics driven by artificial intelligence to support new efficiencies and business insights -- without additional capital investment.

- Blogs

- Providing Drug Supply Support in Complex Environments through IRT

Interactive Response Technology (IRT) is a powerful tool for managing key aspects of the patient journey in clinical trials like randomization and drug dispensation. It is also equally as important when it comes to optimizing the clinical supply chain. Clinical studies have become increasingly complex. Driven by the increased use of technology over the years, they are generating more data than ever before. IRT must evolve to respond to this new clinical trial landscape. IRT innovations are needed for the useful application of data across multiple systems, the automation and streamlining of the patient journey, and the optimization of the clinical supply chain. Clinical technologies like IRT also need to easily adapt to evolving clinical trial protocols while enabling the efficient dispensation of the right drug to the right patient at the right time.

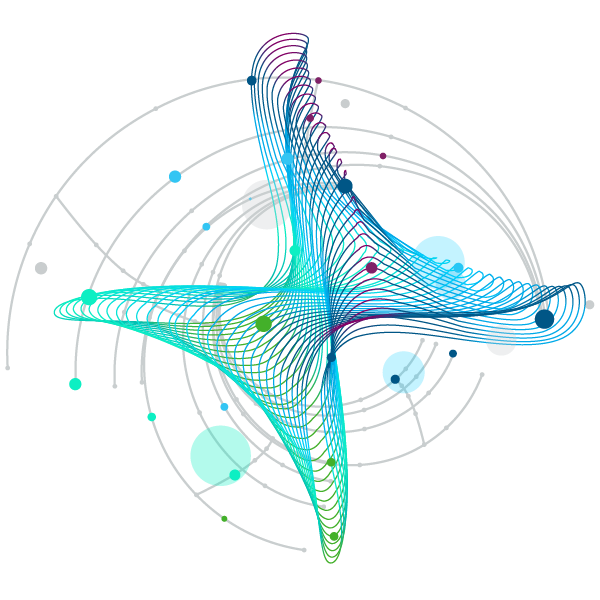

Using real time IRT data for the predictive analysis of both short-term drug needs at sites and long-term drug needs across country, regional and global supply networks allows for the optimization of clinical supply management at the site level while highlighting and mitigating risks to the supply network. The ability to apply predictive data analytic tools to data that indicates the daily supply needs at sites makes it possible to design an optimal supply strategy that reduces the waste of costly clinical supplies, reduces the need for excess shipments and the need for manual oversight. This not only reduces costs significantly but promotes a more efficient, environmentally friendly running of trials, helping sponsors achieve sustainability goals.

As you can see, the ability to optimize clinical supply is critical, but so is the ability to mitigate trial supply stock-outs. Not having the right drug available for a patient at the site will result in protocol deviations, potential issues with patient safety and risks of losing the patient. Even worse, if a stock out happens in the supply network, it could result in a trial pause and an expensive study extension.

In the past, mitigating stock out risks in the face of highly uncertainty clinical recruitment usually led to a high quantity of ‘safety stock’ kept at sites which forced frequent shipments that included small quantities of clinical supply. On average, two-thirds of that supply was wasted at the end of the trial with only one-third being dispensed to patients.

Reaping the benefits of the right IRT partnership

Why is it more important than ever to optimize clinical trial supply – reducing or even eliminating excessive waste and shipment costs? The sharp rise in gas prices and high inflation make optimizing shipping and energy costs an economic imperative. Additionally, trials are experiencing shortages in raw materials and labor – making the conservation of effort and supplies essential. These and many other recent increases in supply chain pressure must be offset.

Using technology to ensure the optimization of shipments & IP resources, consistently and without additional labor or oversight supports sustainability goals while reducing cost and effort.

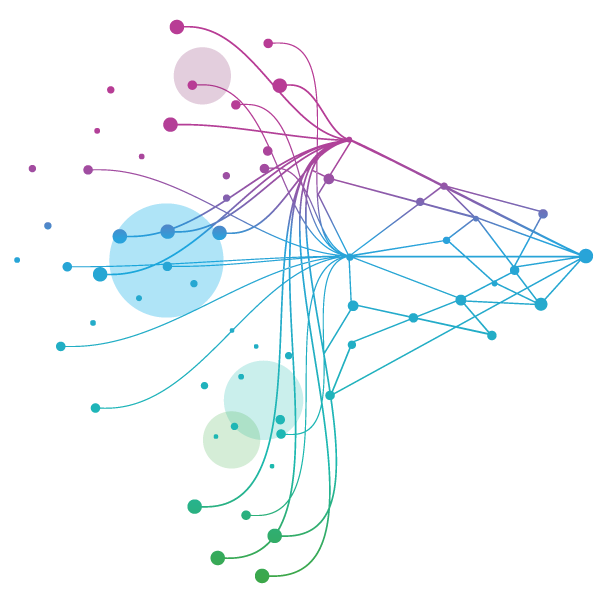

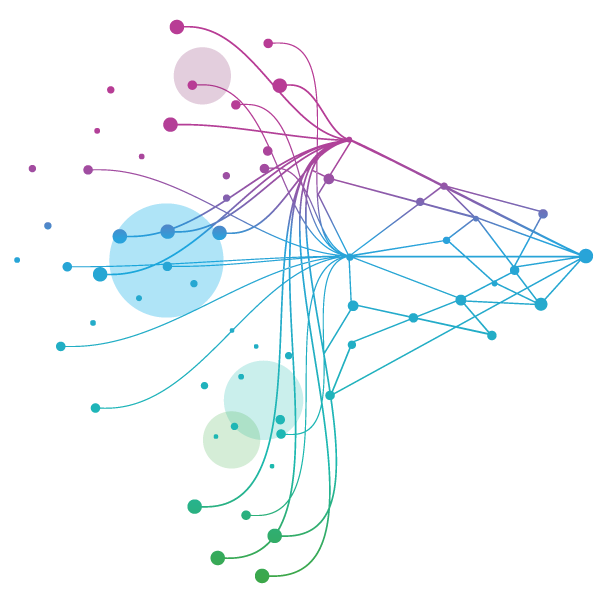

The real-time nature of IRT data makes it ideal to leverage in the creation of predictive analytics and proactive measures that reduce the need for excess shipments and IP waste. By re-evaluating and assigning the most optimal supply strategy for every site, every day, our Supply Automation Value Engine (SAVE) automates resupply decision-making in IRT. To minimize risk, waste, cost and effort, SAVE uses real-time IRT data to drive simple, automated configurations of intelligent supply chain optimization. Through SAVE, we assist our partners in reducing clinical team effort and reducing transportation and IP costs.

5 factors that your IRT partner should address

- Optimize clinical supply planning - In order to reduce drug wastage and shipping costs for clients, forecasting tools, resupply algorithms, and proprietary optimization tools are used. In addition to providing a view into future depot stock trends based on real-time data, online forecasting dashboards and other tools should also include recruitment plans that account for site numbers, patient counts, and recruitment goals in real-time.

- Eliminate manual work and burden - Supply management becomes easier and more cost-effective when it is automated. Automated tools will reduce the burden on sponsors and drug supply managers.

- Complexity management - Managing the clinical drug supply chain in a complex study protocol is essential for ensuring patients receive the right drug at the right time and in the right place.

- Cost optimization strategies for expensive IP and comparator stocks - Comparator drug stocks can be optimized by automated resupply through IRT.

- Eliminate the risk of site stock-outs - To ensure every patient receives the right drug at the right time, studies should be set up with study-specific supply strategies that utilize real-time data.

Interested in learning more about IQVIA’s IRT capabilities or our drug supply optimization tools, check out our site or reach out to schedule a demo.

Stefan Duerr

Stefan has worked in IRT for 16 years and has been with Cenduit IRT, an IQVIA business, since its inception in 2007. He has worked in various project management roles including leading the global project management team at Cenduit. Stefan currently is responsible for client delivery of key customer accounts and heads the Cenduit drug supply center of excellence. He is very passionate about finding innovative solutions for clinical supply challenges. Stefan holds a Master of Science in molecular biology and an international executive MBA of the University of St. Gallen.

You may also be interested in

Using tech enabled solutions to boost productivity and sustainability in clinical trials

Medical Device Trial Integration

Supply Chain Logistics Experts Share Best Practices

IQVIA Integrated Complete Consent IRT eCOA

Related solutions

Ease the burden on your sites and make it easier and more appealing for patients to enroll and remain engaged.

Technology informed by unparalleled Decentralized Trials (DCT) operational experience and delivered at global scale.

Power your decentralized trial with an agile randomization and trial supply management solution that supports supply flexibility and optimization as well as adaptable direct to patient options.