Boost your regulatory productivity.

- Blogs

- Design for Registration: Turning Global Regulatory Complexity into Commercial Advantage

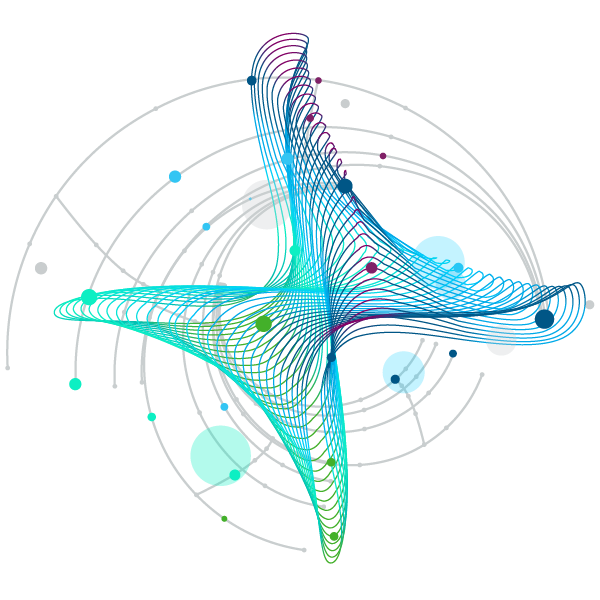

“The more things change, the more they stay the same” is a famous quote attributed to the French writer Alphonse Karr, highlighting the paradoxical constancy underlying apparent change. In the case of global healthcare solutions, the acceleration of global regulatory change and the advancement of product innovation and new technologies—such as SaMD/MDSW and AI—drive a continuous state of change. Regulations don’t just vary by country; they also vary by product type and therapeutic area within vertical healthcare regulations, and additional complexity is layered in through horizontal regulations such as cybersecurity, AI, and data privacy.

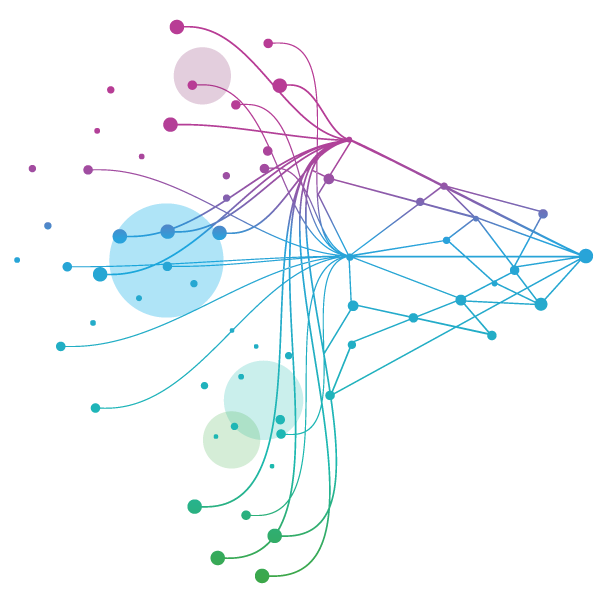

The historically familiar innovation pathway of designing for the U.S. and EU first, and then “going international” after launch, builds in delays to global market access, drives potential redesign activities when other design parameters must be met in global markets, and ultimately slows the global provision of safe and effective patient solutions. A “design for registration” mindset, underpinned by a connected digital ecosystem for QMS, RIM, and Regulatory Intelligence solutions, enables Quality Assurance and Regulatory Affairs (QA/RA) leaders to shorten time to global markets while ensuring the provision of safe and effective patient solutions.

The trap of “US/EU first, international later.”

Most companies still design for the U.S. FDA and European CE marks, and then “switch on” requirements for other international markets after a design freeze. That’s exactly where surprises emerge—country‑specific technical, toxicological, and clinical requirements can drive different design parameters from those accepted by the U.S. and EU. Many markets also require an in‑country authorized representative or responsible person to hold registrations. Each “surprise discovery” means a potential loss of time and money; when a significant design input emerges, it can trigger product redesign activities.

Even when the core submission is strong for the U.S. and EU, content reuse falters when additional global requirements are considered. Different authorities request variations in device descriptions, performance claims, shelf‑life rationales, or cybersecurity attestations. What appears to be a trivial delta becomes a cascade: new protocols, country‑specific labeling and packaging, and rework of the existing product that can trickle down into supplier control activities and updated documentation. The operational signals are familiar: delayed launch dates, pressured remediation, and inventory management challenges. Commercial leaders see this as “regulatory delay,” but in reality it is a design‑input gap surfacing late in global market access activities.

Systematic remediation requires both cultural and procedural change. End‑to‑end digital platforms that connect critical QA/RA activities across global teams can create significant competitive advantage.

Design for Registration: Build global inputs into design control.

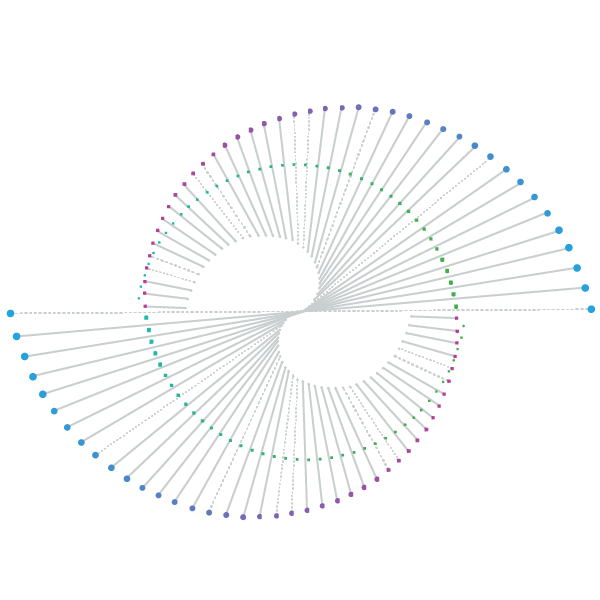

“Beginning with the end in mind” and gathering design requirements beyond the U.S. and EU supports improved global market access—especially where requirements from Japan, China, Russia, Brazil, India, Saudi Arabia, and other countries are considered. Treating global regulatory, clinical, toxicological, labeling, UDI, and cybersecurity inputs as core design requirements increases confidence in “right‑first‑time” activities mandated outside the U.S. and EU.

In practice, this includes:

- Structured requirement intake by market and product family

- Early gap assessments of standards and test methods

- A content strategy that anticipates dossier variations

The goal is right‑first‑time submission management and product registrations that minimize rework driven by localized requirements.

QA/RA teams using a digitally connected backbone of QMS, RIM, and Regulatory Intelligence solutions can optimize communication, content transfer, and coordination with internal and external partners. When these systems are enhanced with AI to improve efficiency, accuracy, resource utilization, and compliance—and supported by analytics for proactive performance management—the benefits to healthcare populations are significant through accelerated access to safe and effective solutions.

Staying ahead of change: Why a connected ecosystem matters.

Global regulation is moving faster than manual monitoring can support. QA/RA professionals face a steep rise in requirements and guidance updates, and managing that volume exceeds the capacity of spreadsheets and email threads. Digital systems that surface early notice of change, map impacts to globally registered products, and identify remediation actions are now essential for predictable global product lifecycle management.

The key capability is connected intelligence—linking a change notice (e.g., updated biocompatibility standard, labeling rule, or cybersecurity expectation) to affected SKUs, registrations, and document content. With digital solutions, global QA/RA teams collaborate in a unified workspace to create a single source of truth that drives approved change plans. When executed well, companies avoid suspended market access and replace reactive “firefighting” with planned lifecycle management, including sequencing submissions, aligning inventory runouts, and negotiating with distributors based on reliable data.

The commercial impact is clear: earlier market access, fewer supply disruptions, and improved operational discipline.

IQVIA SmartSolve – A single, AI‑enabled platform for QMS and RIM activities

Digital QMS and RIM solutions help QA/RA professionals navigate global regulatory complexity and ensure safe and effective solutions across the product lifecycle. By connecting quality records across change plans, documentation, local submissions, and product registrations, organizations reduce risk, improve efficiency, and free QA/RA teams to focus on technical, strategic, and market access activities.

SmartSolve is one such platform—purpose‑built to optimize QA/RA activities. The AI‑enabled solution unifies QMS and RIM, and has been recognized in recent years with:

- MedTech Breakthrough “Best Use of AI in Healthcare” (2024)

- Frost & Sullivan Global Customer Value Leadership (2024)

- Bronze Stevie Award for Healthcare Technology Solution (2025)

To speak with an expert, contact eQMS@iqvia.com.

About SmartSolve®: SmartSolve is an AI-enabled, Microsoft Azure-based platform that helps Life Sciences organizations streamline and automate global quality management and regulatory compliance. SmartSolve® eQMS centralizes enterprise-wide quality processes, from design and manufacturing to post-market surveillance, while SmartSolve® RIM manages regulatory submissions, product registrations, and health authority interactions. Built on industry best practices, SmartSolve connects teams, data, and workflows in a single platform to drive an optimized focus on patient safety, product quality and commercial performance.

You may also be interested in

Embracing Change and Dealing With It

The Future of RIM is Cross-functional Integration

Ready your organization to support the next generation of RIM.

Related solutions

Outdated compliance practices aren't viable amid evolving market and regulatory changes. IQVIA’s award-winning, end-to-end quality management system streamlines the product value chain, accelerates market entry, safeguards companies and patient safety, and meets complex regulatory demands.

From manufacturing oversight to regulatory requirements, manage quality across your organization with a single enterprise software solution.

Automate and standardize your regulatory management, from correspondence and commitments to registration and tracking.

Meet the challenge of changing stakeholder demands and increasing cost constraints with IQVIA's integrated technology services and analytics-driven offerings.

Drive global market access with AI-enabled regulatory management